Technical Specifications

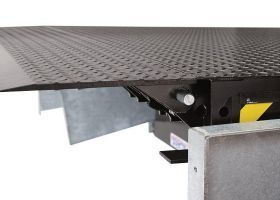

The platform, beams and lip are made from high tensile steel (S355J0 / STEEL 52). Both the platform and the lip have a tear plate surface (8/10 mm and 13/15 mm respectively), making them suitable for 3-wheel forklift trucks. Pre-equipped with cables and cable tree between leveller and control box for a quick and fast installation.

Black Anti-Corrosion Coating and galvanised frame components to protect the dock leveller against all weather conditions. Standard protection is an anti-corrosive coating and paint finish of 80 micrometres total thickness. other colours are available upon request.

Below Dock Control (BDC) is standard on all S-Series levellers. Automatic BDC is an option available and offers evern more convenience for end-cargo loading and unloading. The S-Series is in accordance with the EN 1398 Directive. Optimum safety is provided due to the fact that the S-Series is equipped with a hose burst valve aswell as an electrical emergency stop valve.